NSF International is a globally recognized authority dedicated to protecting public health and safety. With a transparent certification process and stringent standards, NSF certification is widely regarded as a symbol of quality in water filtration products.?

NSF 53 certification is a rigorous standard for drinking water purification products, ensuring they effectively remove harmful substances like heavy metals (lead, mercury), VOCs, and microorganisms. Certified products undergo independent testing to confirm reliable filtration and safeguard health. Globally recognized and rare, this certification highlights superior quality and the manufacturer's commitment to safety and responsibility.?

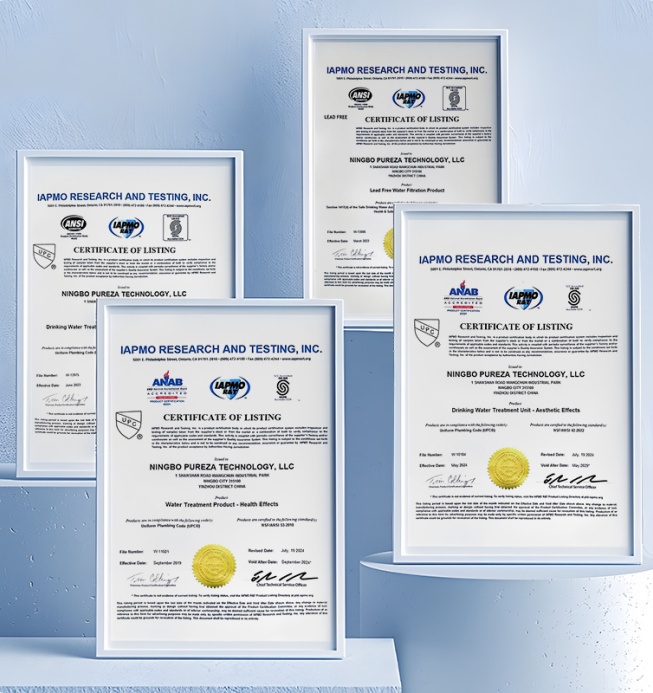

International Certifications: Our products hold multiple global certifications, including upgraded NSF 53 certification for the entire range, significantly enhancing market competitiveness and boosting clients' brand market share.

Factory Upgrade: We have dedicated injection molding, carbon rod production, assembly, and packaging workshops, ensuring a full supply chain to minimize risks. In 2025, we will fully upgrade our laboratory to meet customer testing needs and improve testing efficiency.

Can't Find Target Products? contact us!

High-Efficiency Filtration Materials: We use precision-manufactured, multi-layer filter materials, including activated carbon and microfiltration membranes, to effectively remove heavy metals, bacteria, and chemical contaminants.

Innovative Product Design: Designed to meet diverse user needs, our filters and water dispensers ensure high filtration efficiency while focusing on convenience and user experience.

Leading Technological Innovation: With our self-developed filtration structure, our products offer efficient filtration, longer service life, and reduced replacement frequency, providing users with a long-lasting, reliable experience.

Supplier Auditing: Working only with supplier that meet international standards .

Material Testing: Each batch of raw materials undergoes preliminary testing before entering production.

Real-Time Monitoring: Ensure each process step meets technical specifications.

Semi-Finished Product Testing: Timely identify and eliminate potential issues to ensure the stability of the final product's quality.

Filtration Efficiency Testing: Ensure compliance with or exceeding NSF 53 standards.

Flow Rate & Durability Testing: Ensure optimal performance, durability and product's lifespan.

Physical Performance Testing: Guarantee durability and safety.

Heavy Metal Analyzer: Ensure filters meets NSF 53 removal requirements.

Microbial Testing Equipment:Assess the filter’s ability to remove bacteria and other harmful microorganisms.

Constant-Flow Pressure Tester: Ensure filters do not leak or break under high-pressure conditions.Ensure consistent functionality throughout its lifespan.

Batch Testing: Each batch undergoes sampling and testing to ensure consistency and stability in product quality.

High-Frequency Inspections: Frequent quality checks are conducted at every stage of production to ensure all processes.

Final Inspection: Finished products undergo a comprehensive inspection before shipment.

Yes, We are the source factory.We offer both OEM and ODM services, allowing you to customize Water purification products to meet your specific requirements, including branding, packaging, and filter specifications.

Our water filters are certified with industry-leading standards including NSF 42, NSF 53, NSF 401, CE, FDA, EPA, and ISO, ensuring the highest quality and safety for your customers.

NSF 53 certified filters can remove a range of contaminants, including but not limited to heavy metals (such as lead and mercury), volatile organic compounds (VOCs), harmful chemicals (such as trichloroethylene), chlorine, and chloramines, enhancing water safety.